Due to the fact that the objects in the textile processing are various fibers or yarns, they are originally flexible objects that are prone to deformation under external forces. Generally, during the unwinding and rewinding of materials, the diameter of the coil will constantly change, while the tension of the coil will constantly change with the change of the diameter. In this case, if the tension of the coil is not controlled, the coil will experience wrinkles, looseness, and thickness changes. In severe cases, the coil may fracture. In addition, in the printing process, changes in tension can cause the paper to stretch or shrink, leading to immediate registration errors. Therefore, it is necessary to control the tension of the coil.

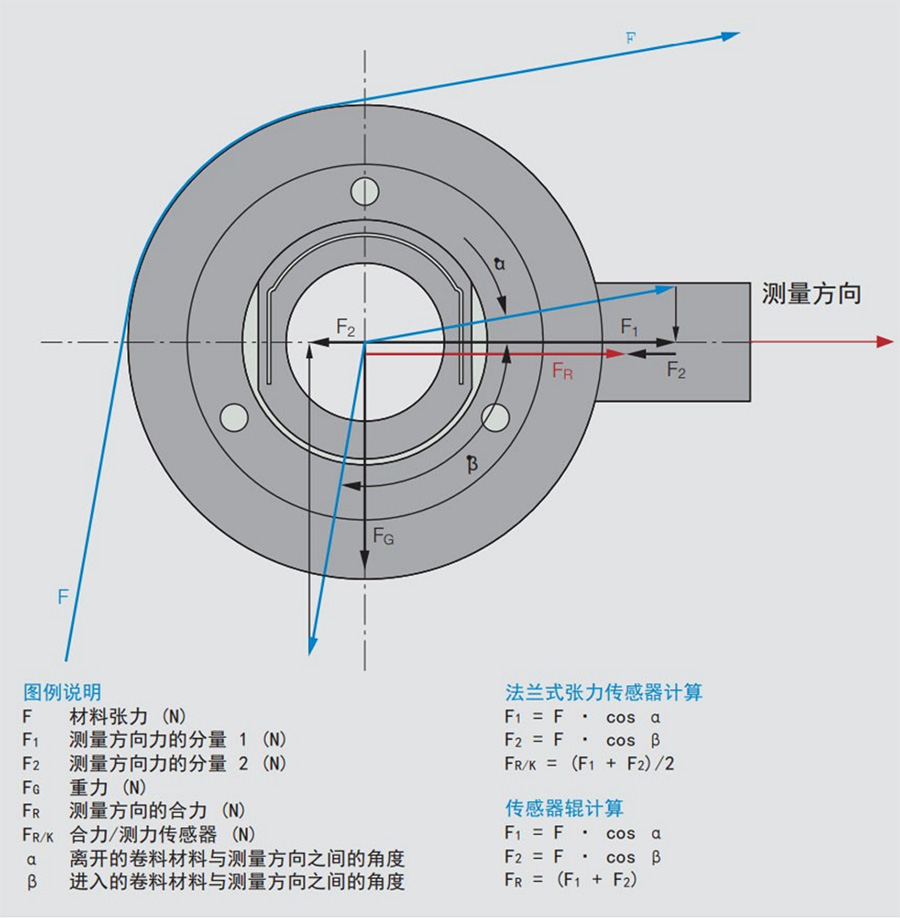

Flange tension sensor

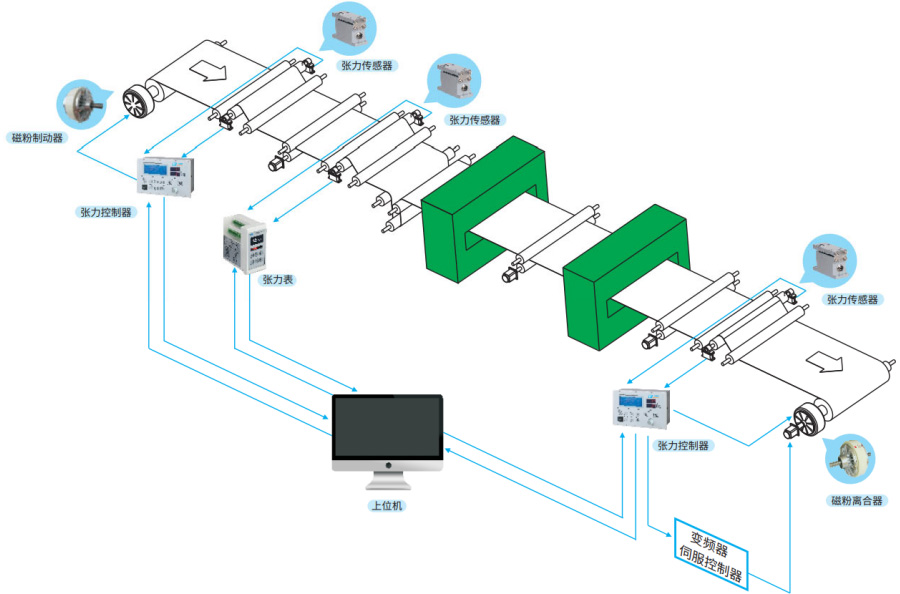

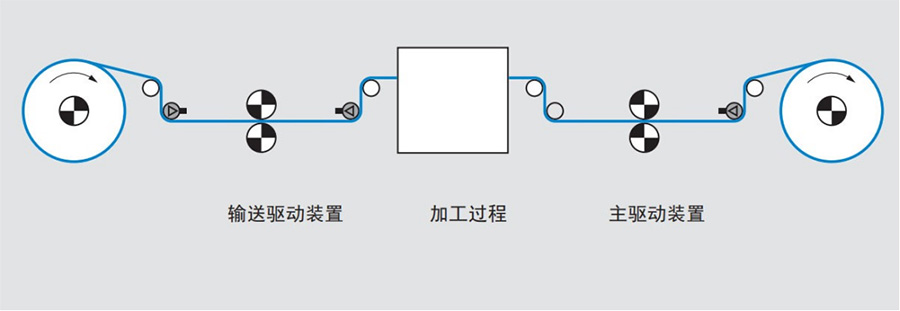

The flange type tension sensor is almost used in all production lines for processing or tempering strip materials. Especially in front of the processing station, it is essential to transport the coil material with continuous material tension.

application

The winding angle of the measuring device is 90 ° (horizontal vertical and the measurement direction is horizontal) to ensure optimal sensing of material tension. Only by sensing material tension from both ends can measurement errors caused by lateral displacement of the material and asymmetric distribution of material tension be avoided. The force sensor connected to the closed control circuit should be installed as close to the actuator as possible.

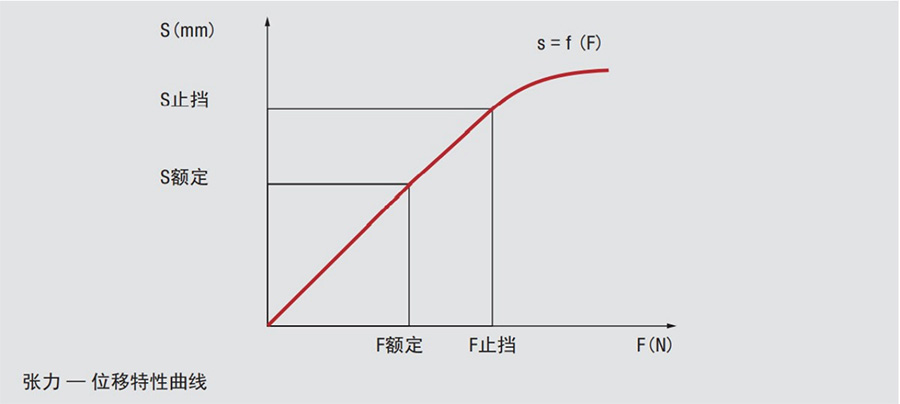

calibration

Until the mechanical stop, the tension displacement characteristic curve forms a straight line. Except for the PD 25 series, all measuring sensors are calibrated to their rated measuring force. A safety factor of 50% to 100% was considered between the rated measuring force and the mechanical stop to compensate for the asymmetric distribution of material tension.

Copyright © Shenzhen DOT LINK Sensing Technology Co., Ltd 粤ICP备2023125867号